The Ultimate Guide to Polishing Zirconia in 2025: A Complete Workflow from Pre-polishing to Mirror Finish

In the modern dental laboratory, achieving a perfect finish on zirconia restorations is no longer a mere final touch—it is a critical measure of quality, clinical longevity, and patient satisfaction. While glazing has been a traditional method, the industry’s pursuit of superior aesthetics and biocompatibility has shifted the focus to mechanical polishing. However, many technicians still struggle with inconsistent results, wasted time, and the risk of damaging costly restorations. This guide is your definitive resource to master the science of “dental finishing and polishing”, transforming it from a frustrating art into a predictable, highly efficient process.

This comprehensive workflow, designed for ambitious dental labs and technicians, will detail every critical step, from initial contouring to achieving a spectacular, durable mirror shine, ensuring your zirconia work stands out for its quality and precision.

Polishing vs. Glazing: Why Mechanical Polishing is the Gold Standard for Modern Zirconia Restorations

The debate between polishing and glazing is over. While glazing can offer a quick shine, its long-term performance and clinical implications fall short of a meticulously polished surface. For any high-quality Lab Polishers, understanding these differences is the first step towards excellence.

The Hidden Risks of Glaze: Beyond the Superficial Shine

- Micro-peeling and Wear: Over time, the glaze layer can wear down or chip away in the abrasive oral environment, leaving a rough, plaque-retentive surface.

- Unnatural Aesthetics: Glazing can sometimes create a thick, overly reflective layer that masks the natural translucency of modern zirconia materials, resulting in a less lifelike appearance.

- Stain Accumulation: Once the glaze is compromised, the underlying surface can be more susceptible to staining.

The Clinical Superiority of a Polished Zirconia Surface

- Kindness to Opposing Dentition: Numerous studies have shown that a highly polished zirconia surface is significantly less abrasive to opposing natural teeth than a glazed surface. This is a crucial factor for long-term oral health.

- Plaque Resistance & Periodontal Health: The ultra-smooth finish achieved through mechanical polishing creates a surface that is highly resistant to plaque and biofilm accumulation, promoting better gingival health around the restoration.

- Unmatched Natural Luster: True mechanical polishing works with the material itself, bringing out the inherent beauty and translucency of the zirconia. The result is a deep, vital luster that mimics natural enamel far more accurately than any glaze.

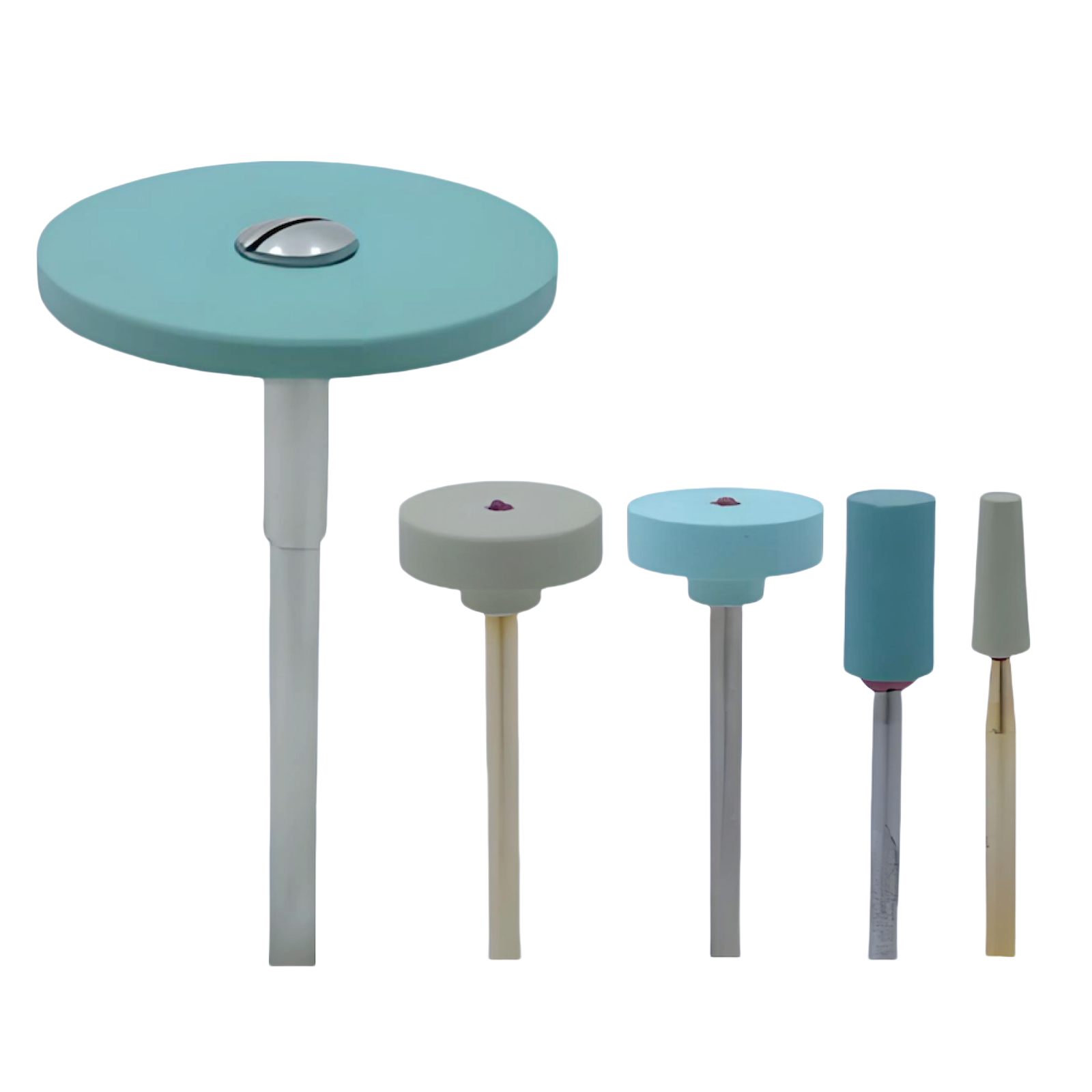

The Foundation of Success: Choosing the Right Dental Polishing tools

Success in polishing is impossible without the right tools. The interaction between the abrasive particles and the zirconia surface is a precise science. Using a generic Dental Polishing Kit is a recipe for failure; you need a system designed specifically for the hardness and characteristics of zirconia.

The Science of Abrasion: Diamond Grit and Binders

- Diamond Grit: The size and density of diamond particles embedded in the polisher determine its cutting efficiency and the smoothness of the resulting surface. A multi-step system uses progressively finer grits to erase scratches from the previous stage.

- Flexible Binder: The binder material (often silicone or rubber) holds the diamond particles. A high-quality binder dissipates heat effectively—preventing thermal damage to the zirconia—and provides the right flexibility to adapt to complex crown anatomy.

The ERADENT Solution: A System Engineered for Zirconia

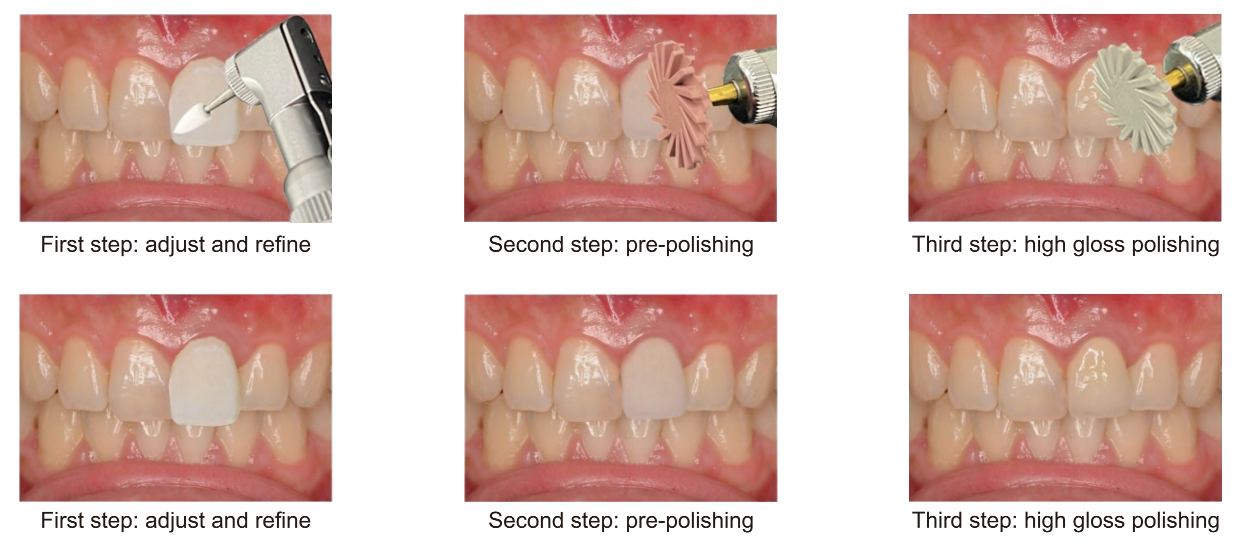

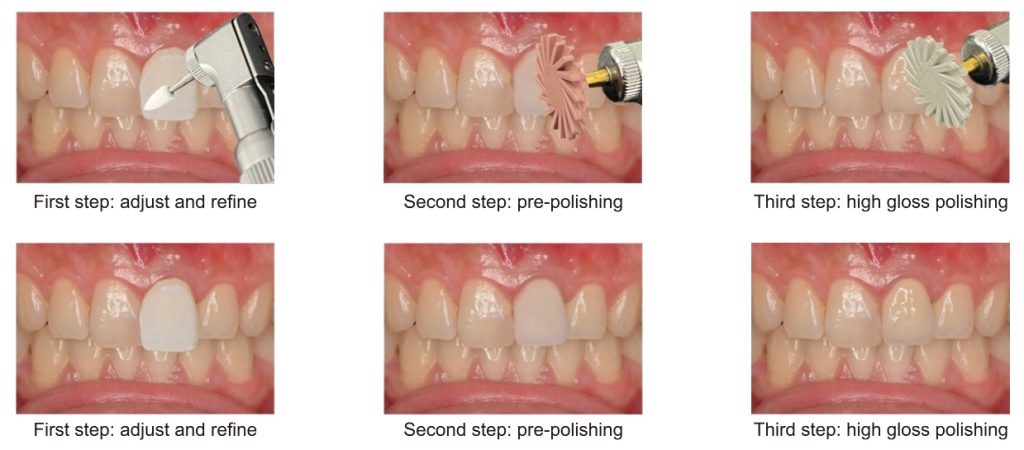

The Core Workflow: A Step-by-Step Guide to a Flawless Mirror Finish

Step 1: Adjustment and Pre-polishing (The Smoothing Stage)

- Objective: To remove sprue marks, perform fine occlusal and contact adjustments, and smooth any roughness left from the milling process. This initial step creates a uniform, scratch-free canvas.

- Tools Used: Fine-grit diamond stones from the ERADENT kit (e.g., instruments like SDH111D, SDH021D). These are designed for controlled material removal without causing micro-fractures.

- Key Parameters:

- Recommended RPM: 10,000 – 15,000 RPM

- Pressure: Use light, intermittent “painting” strokes. Let the diamond particles do the work.

- Pro Tip: Always keep the instrument moving. Lingering in one spot can generate excessive heat.

Step 2: Fine Polishing (The Satin Finish Stage)

- Objective: To erase all fine scratches from the adjustment stage and begin developing a smooth, semi-gloss, satin-like surface. The restoration should start to exhibit a visible sheen.

- Tools Used: Medium-grit polishers from the ERADENT kit (e.g., the pink or red polishers like RDH066, RDH166). These flexible polishers conform to the tooth’s anatomy.

- Key Parameters:

- Recommended RPM: 10,000 – 15,000 RPM

- Pressure: Light, consistent pressure is key.

- Pro Tip: After this stage, inspect the surface under magnification. It should be completely smooth and uniform, with no visible scratches, before proceeding.

Step 3: High-Gloss Polishing (The Mirror Finish Stage)

- Objective: To bring the surface to a final, brilliant, mirror-like luster that is extremely smooth and plaque-resistant.

- Tools Used: Extra-fine grit polishers from the ERADENT kit (e.g., the yellow or light-colored polishers like RDH068, RDH168).

- Key Parameters (Corrected based on official specifications):

- Recommended RPM: 10,000 – 15,000 RPM

- Pressure: Use a very light, almost feather-like touch. The shine comes from burnishing the surface, not from aggressive pressure.

- Pro Tip: For the ultimate “wet look,” you can use a felt wheel with a sub-micron diamond polishing paste as a final optional step, but the ERADENT system is designed to achieve a high gloss without it.

Why Partner with ERADENT as Your Dental Polisher Supplier?

- A One-Stop Solution: Simplify your procurement by sourcing a full range of compatible materials and tools from a single, reliable supplier.

- OEM/ODM Capabilities: We offer flexible manufacturing options to meet the specific needs of dental distributors and large labs, helping you build your own brand.

- Proven Quality: With over 30 years of combined experience in the dental industry and partnerships with over 50 high-quality factories, we ensure every product meets rigorous international standards.

- Global Reach: We have established a strong presence in the Middle East, Turkey, Russia, Southeast Asia, Latin America, and Europe.

FAQ: Answering Your Key Questions

Q1: Why is a multi-step polishing system necessary for zirconia?

A multi-step system is crucial because of zirconia’s extreme hardness. Each step uses a specifically sized diamond grit to systematically remove the scratches left by the previous, coarser step. Skipping a step will leave deep scratches that cannot be polished out, resulting in a dull finish.

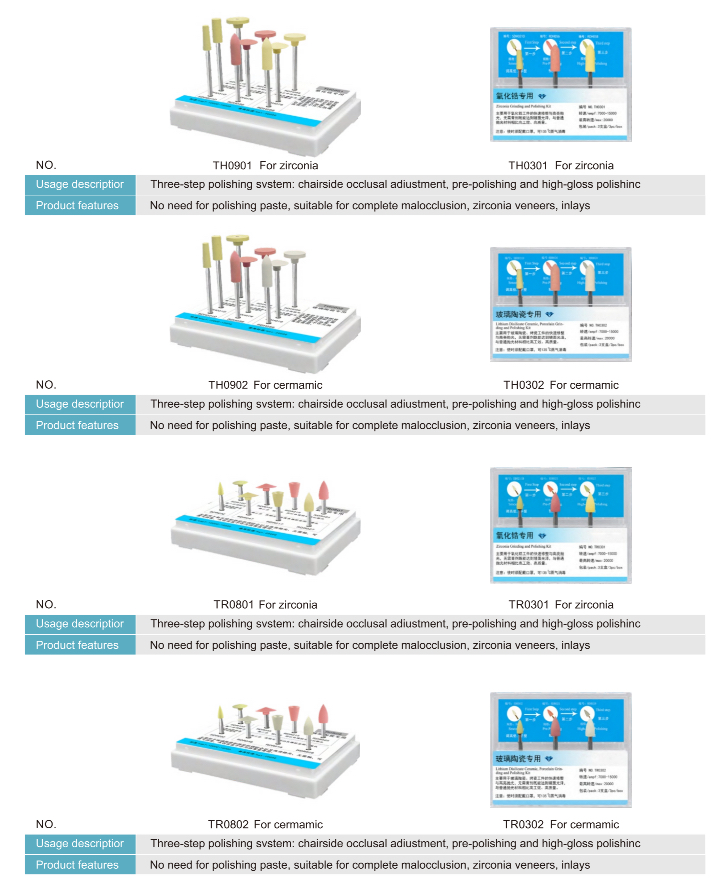

Q2: Can I use the same polishing kit for zirconia, glass-ceramic, and composites?

It is not recommended. Each material has a unique hardness and composition. Using Zirconia Polishing tools on a softer composite can be too aggressive, while a composite polisher will be ineffective on zirconia. ERADENT offers specialized kits for each material to ensure optimal results.

Q3: How can I order ERADENT’s Dental Polishing Kits for my lab or distribution business?

You can explore our full product catalog and make an inquiry directly through our official website. Our sales team offers 7*24 quick response by WhatsApp for immediate assistance.

Conclusion: Elevate Your Restorations with a Flawless Finishing Protocol

Mastering the art and science of zirconia polishing is a direct investment in the quality of your lab’s output and its reputation. By abandoning outdated glazing techniques in favor of a standardized mechanical polishing workflow, you can deliver restorations that are more beautiful, more durable, and healthier for the patient.

A systematic approach using a high-quality, purpose-built Dental Polishing Kit like the ERADENT three-step system removes guesswork, boosts efficiency, and guarantees consistently spectacular results.

If you are looking to elevate your finishing protocol, reduce remakes, and partner with a reliable Dental Polisher Supplier that understands the demands of the modern dental market, your search ends here.

Ready to achieve the perfect mirror finish? Visit our official website to explore our complete range of dental polishing solutions and request your quote today.