Zirconia Grinding

ERADENT’s Zirconia Grinding and Polishing Bur combines diamond abrasives with zirconia-enhanced bonding technology, designed for rapid dry finishing of zirconia crowns, bridges, and abutments. Optimized for chairside and lab workflows, it eliminates water-cooling requirements while maintaining ≤2°C temperature rise at 25,000 RPM

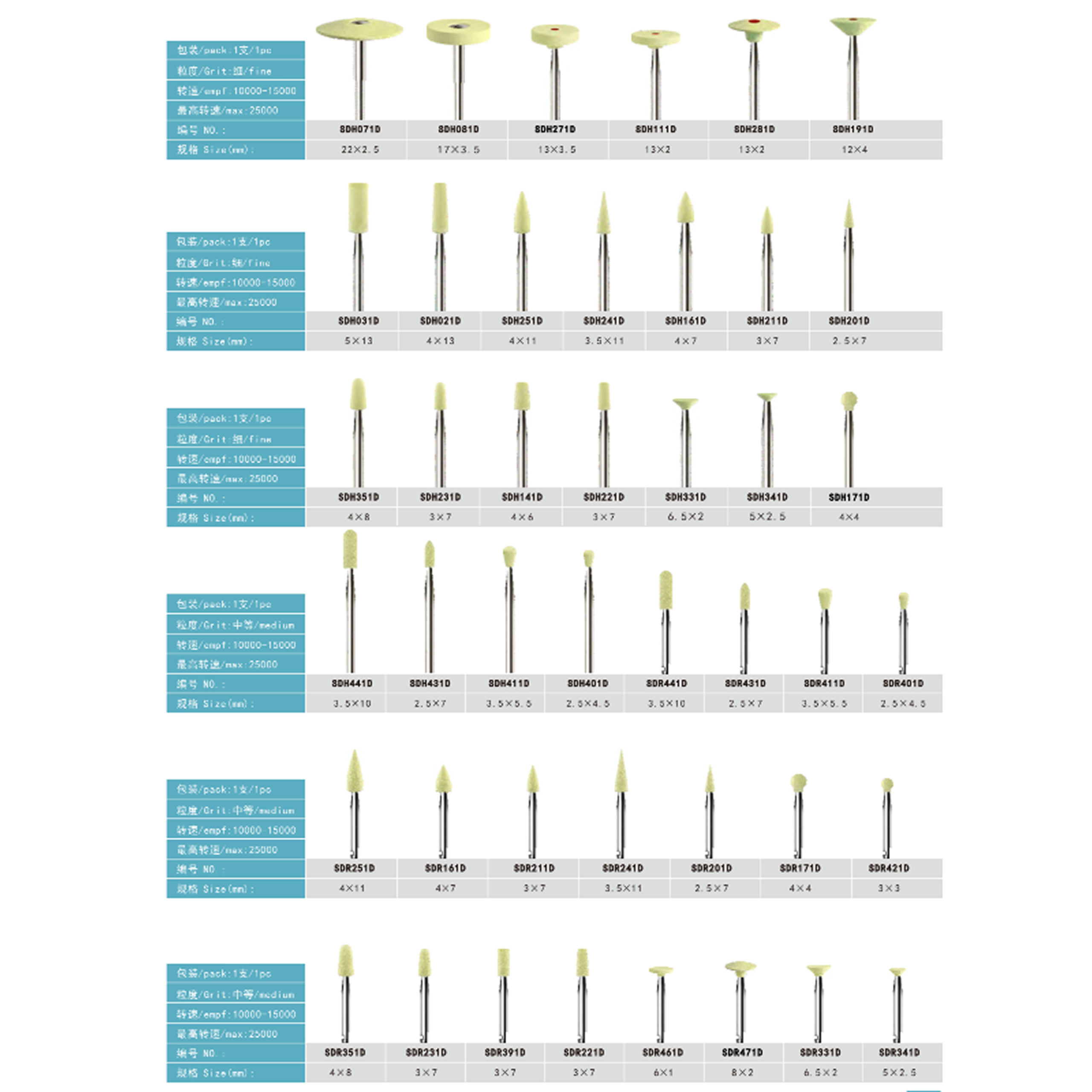

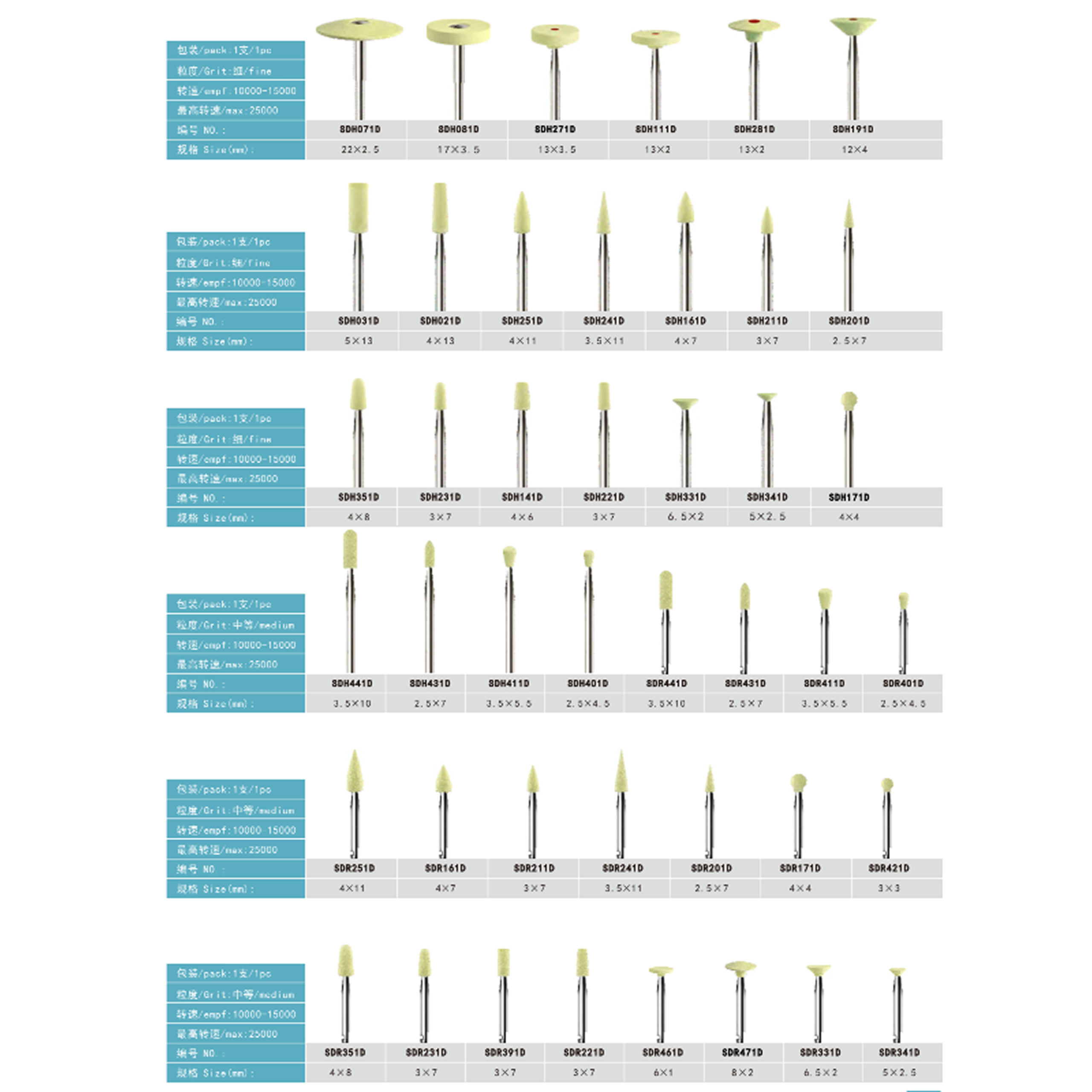

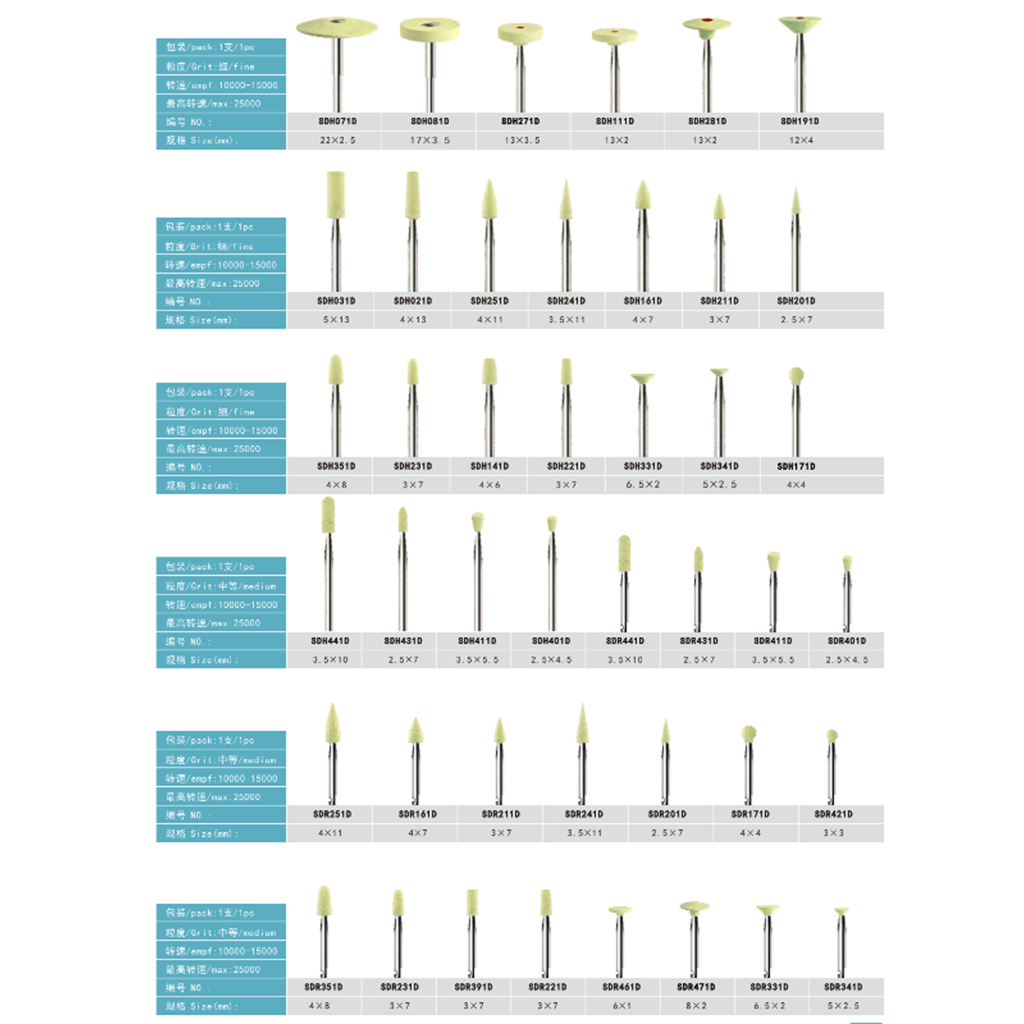

Specification

| Parameter | Details |

| Abrasive Composition | Diamond-zirconia hybrid matrix (density 6.0g/cm³, hardness 1100GPa) |

| Grit | Medium (40–60 μm) |

| Speed Compatibility | 7,000–25,000 RPM (optimal performance at 20,000–28,000 RPM) |

| Shank Diameter | 2.35 mm (ISO 1797-1 compliant) |

| Thermal Stability | Heat-resistant up to 120°C (dry operation certified) |

| Packaging | Sterile single-unit plastic case (10 units/display box) |

Advantage

- Waterless Operation: Proprietary cooling channels reduce friction heat by 60% vs. conventional burs.

- Dual-Action Efficiency:

- Step 1: 150 μm diamond grit removes zirconia excess at 0.2 mm/sec (lab-tested)

- Step 2: 10 μm polishing achieves Ra ≤0.1 μm surface roughness

- Extended Lifespan: 3x longer durability than resin-bonded alternatives (50+ restorations/bur).

- Multi-Material Adaptability: Effective on:

- Zirconia: Full-contour crowns & hybrid abutments

- Lithium Disilicate: Margin refinement without chipping

- PMMA: Denture base adjustments

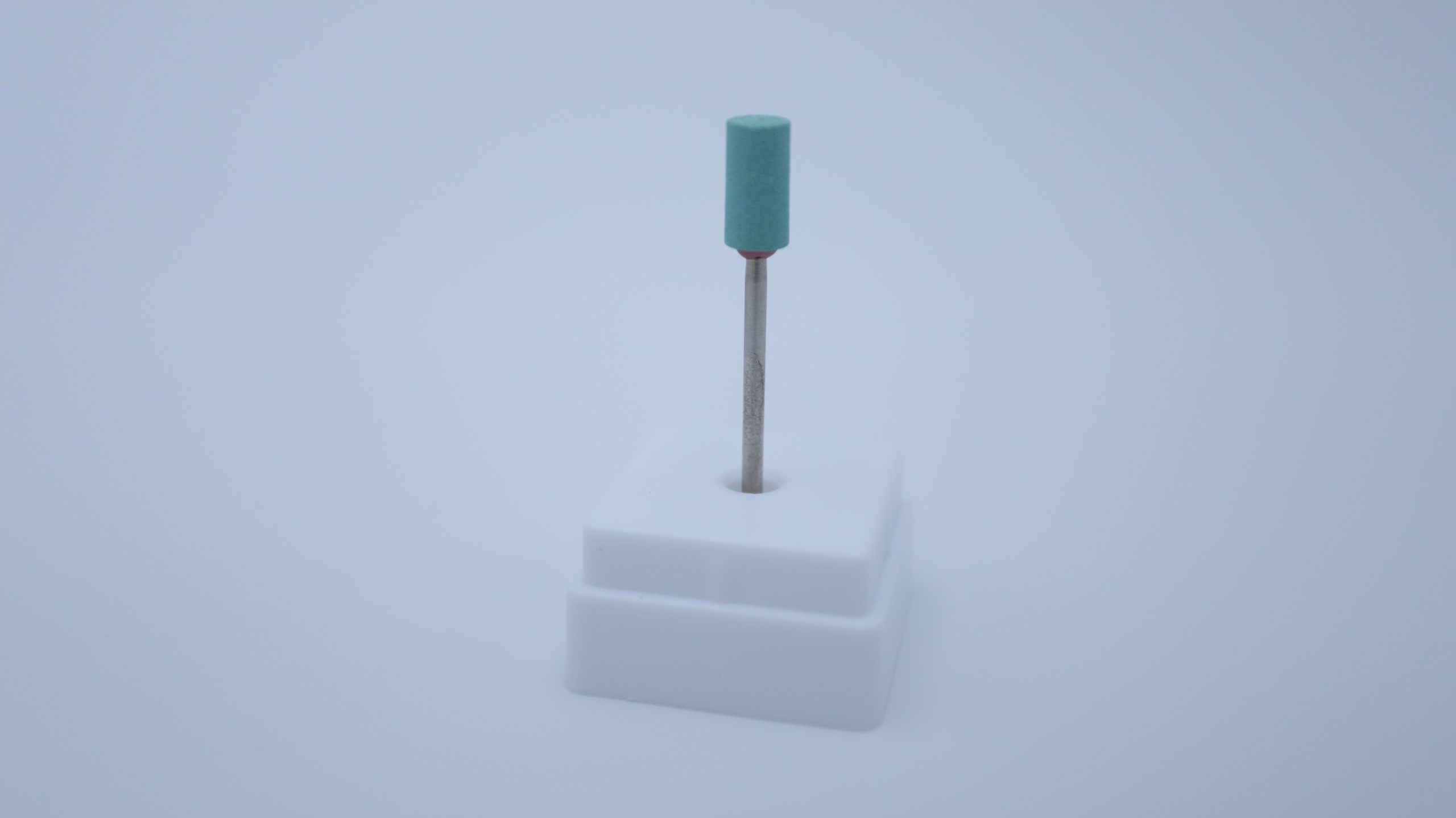

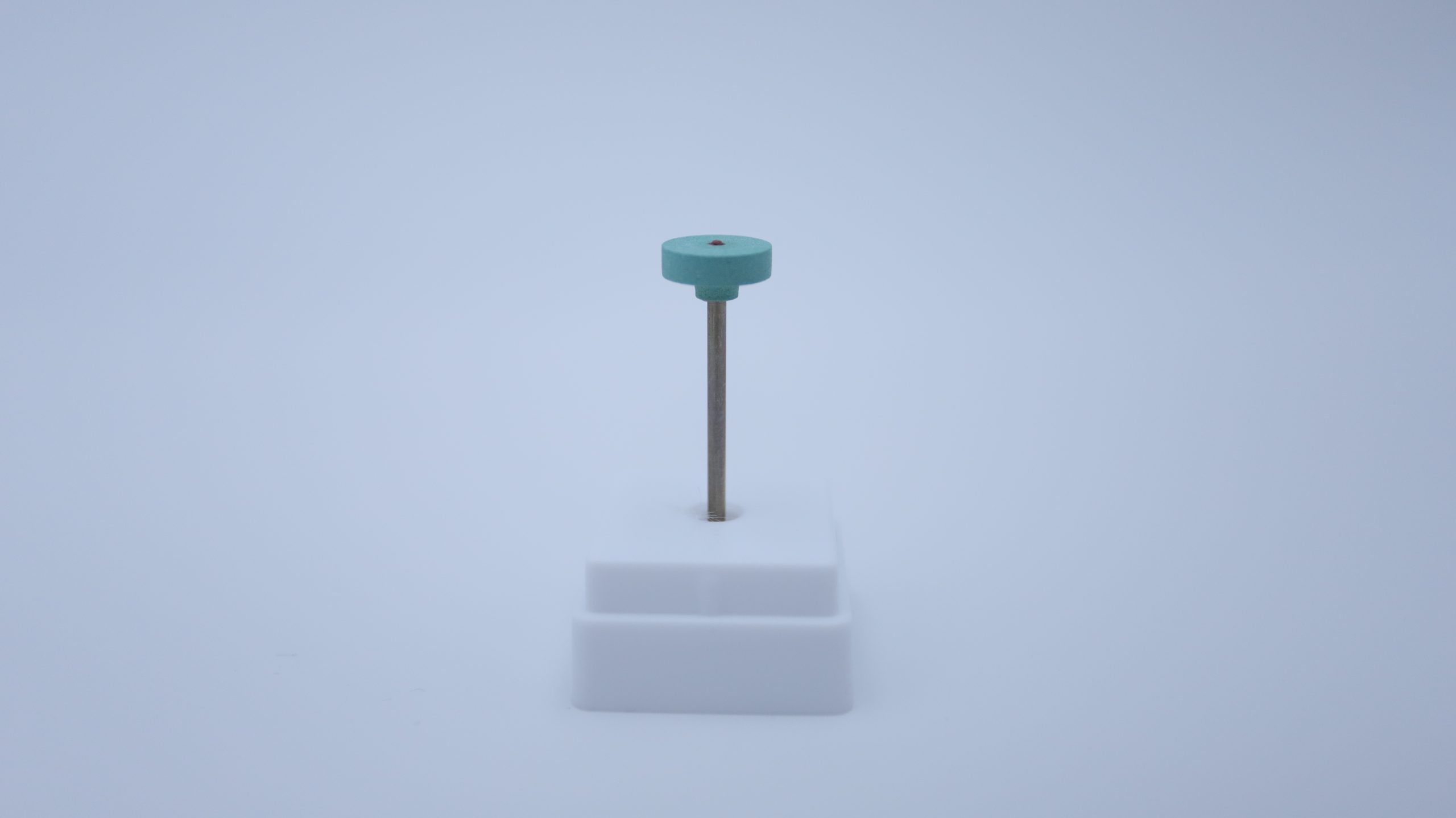

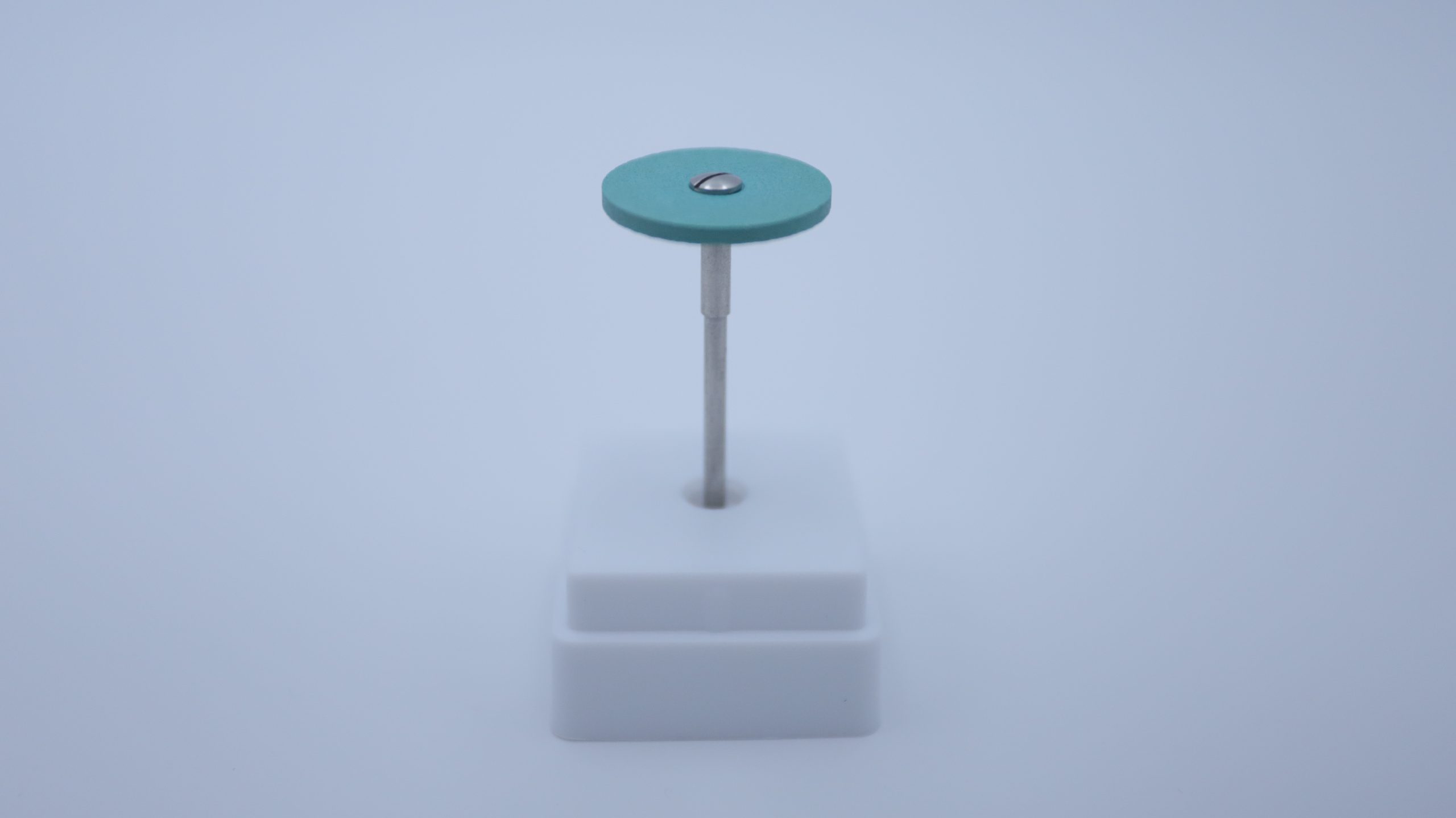

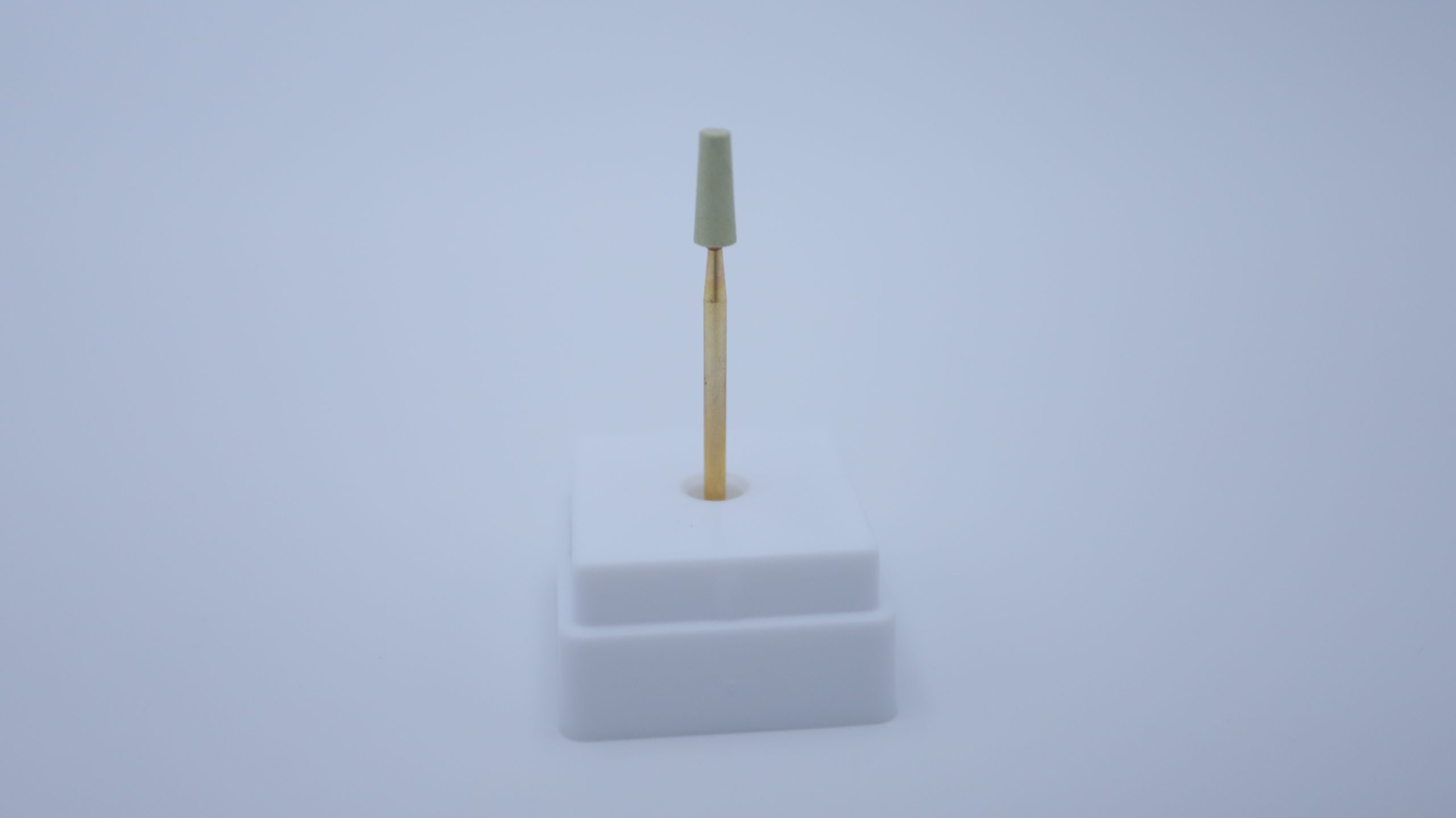

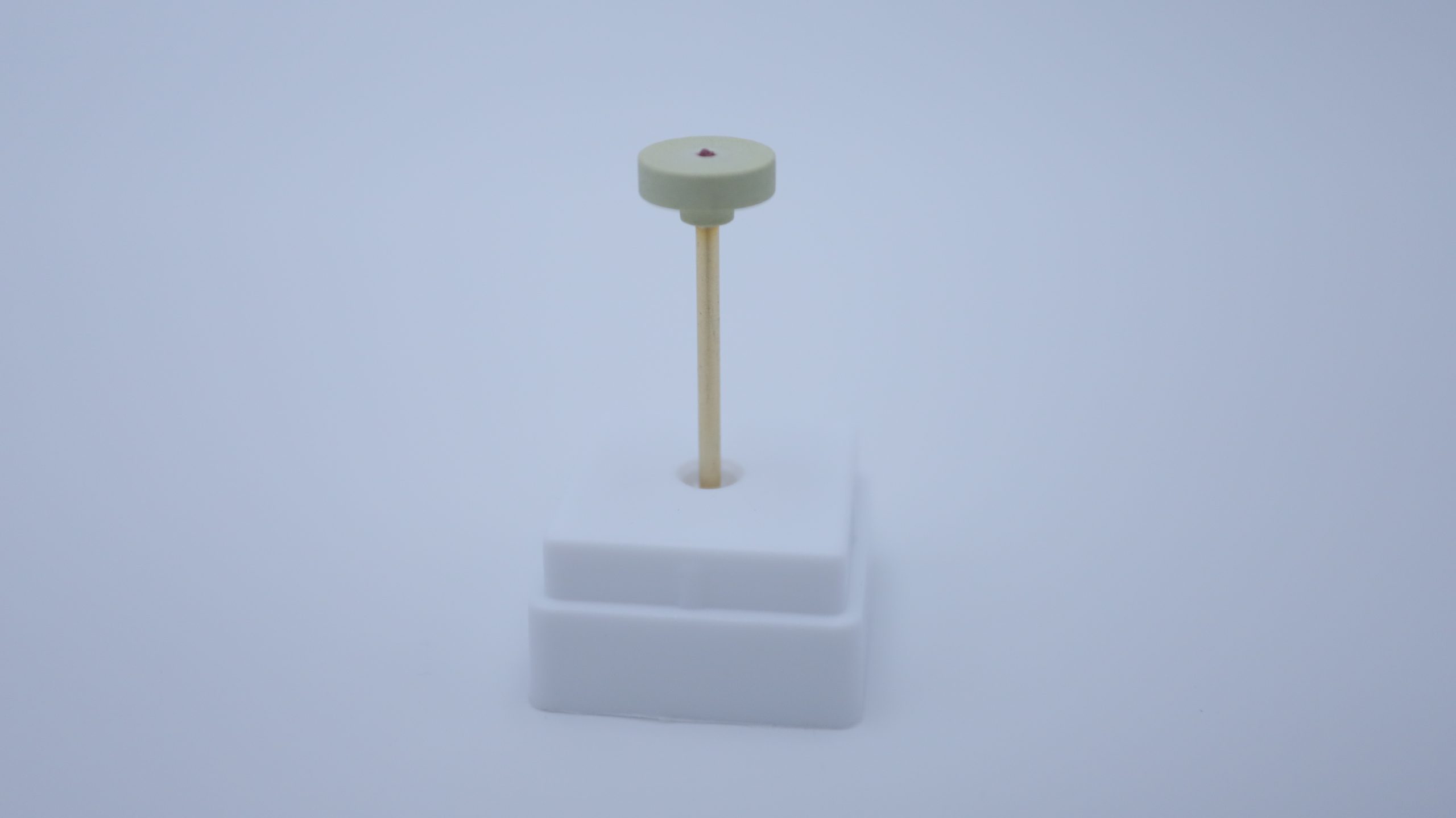

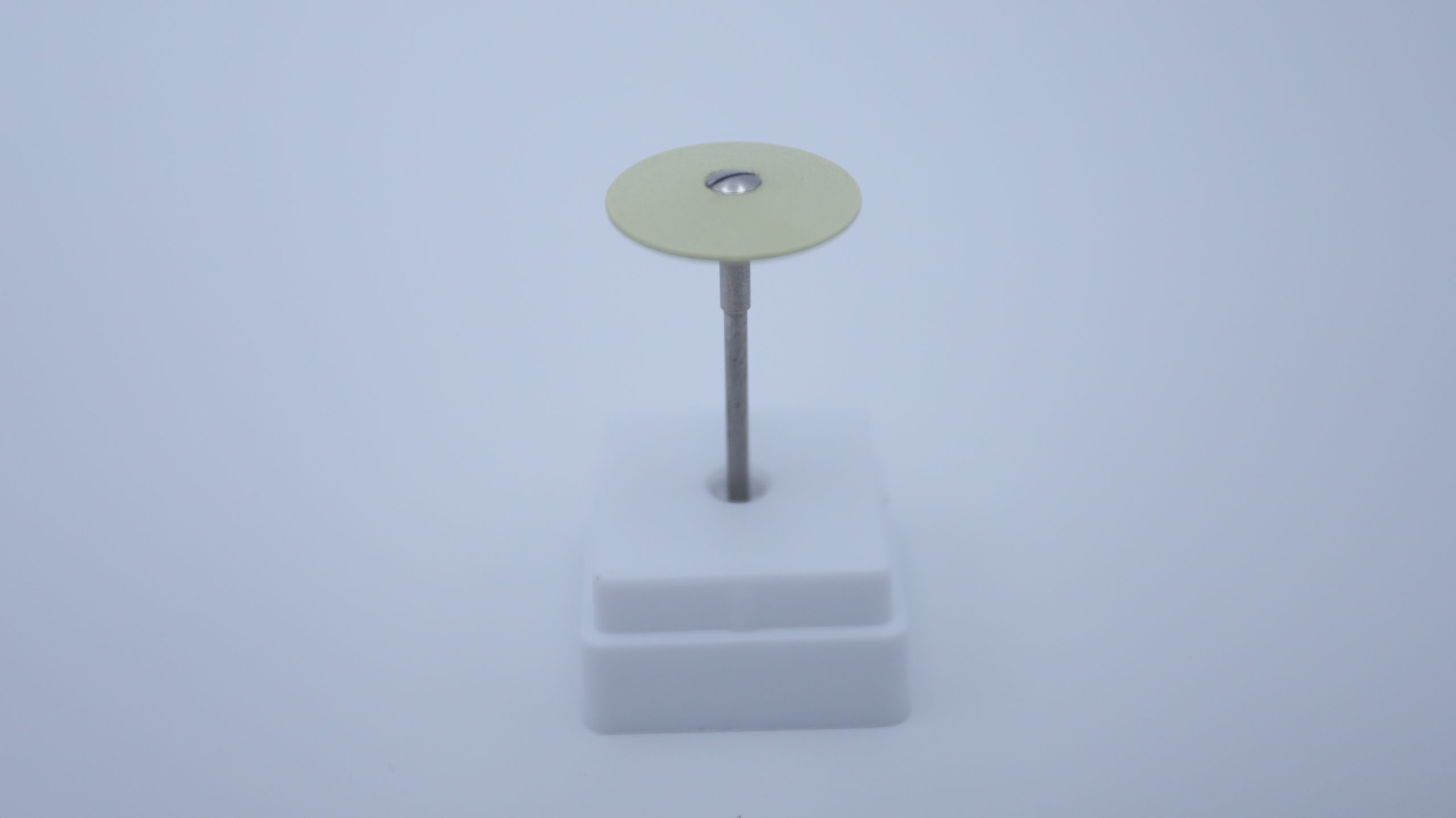

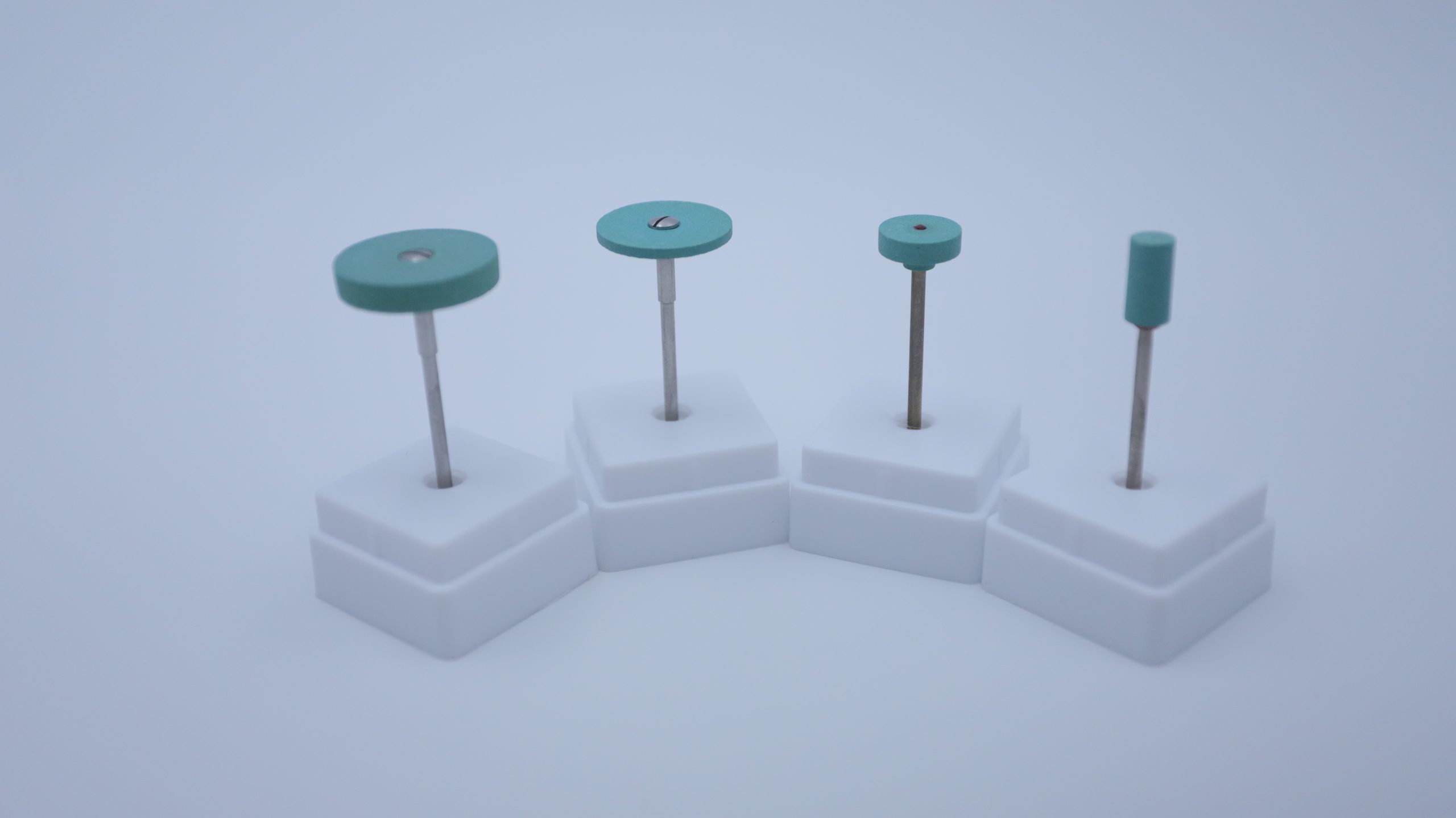

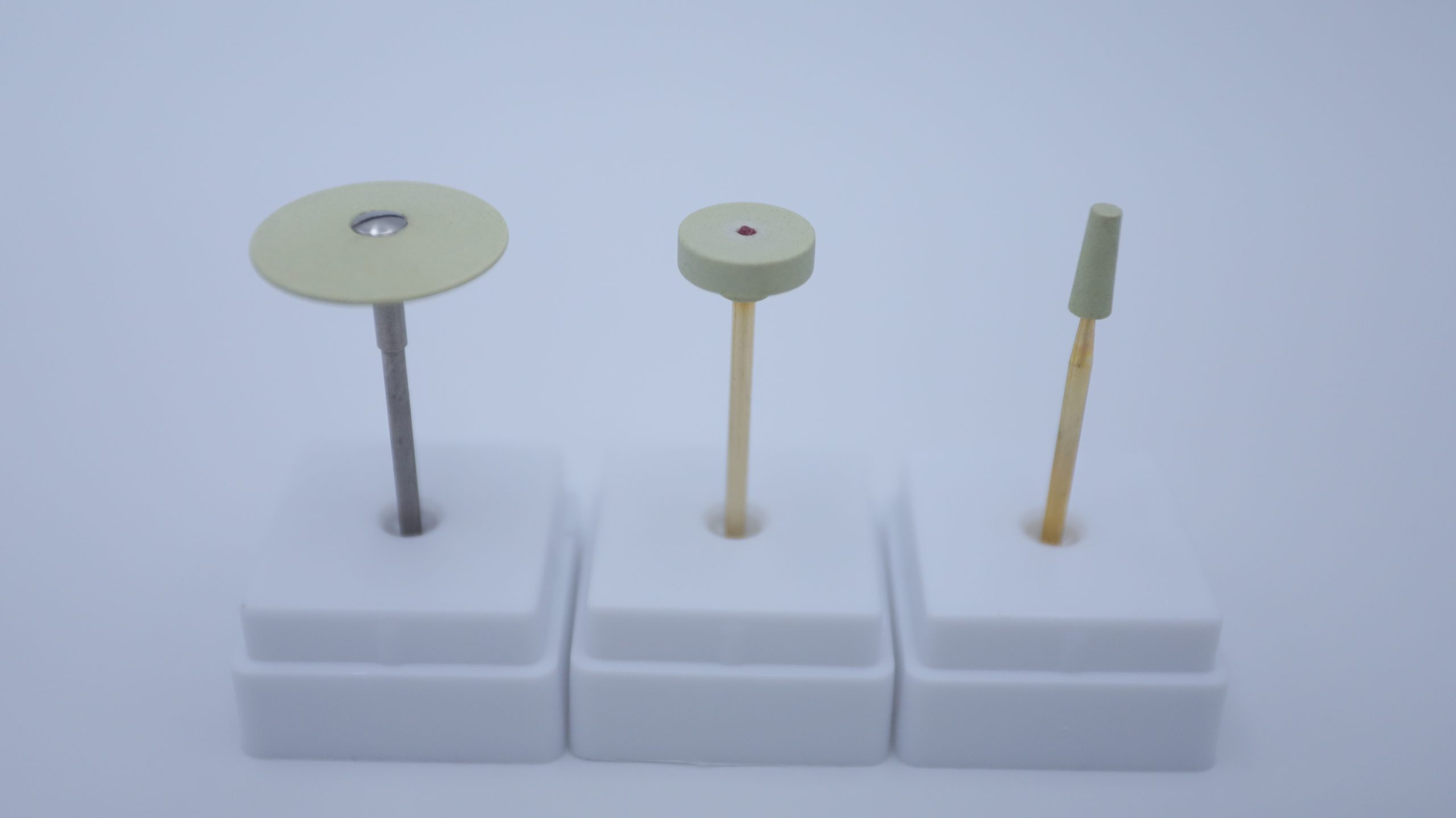

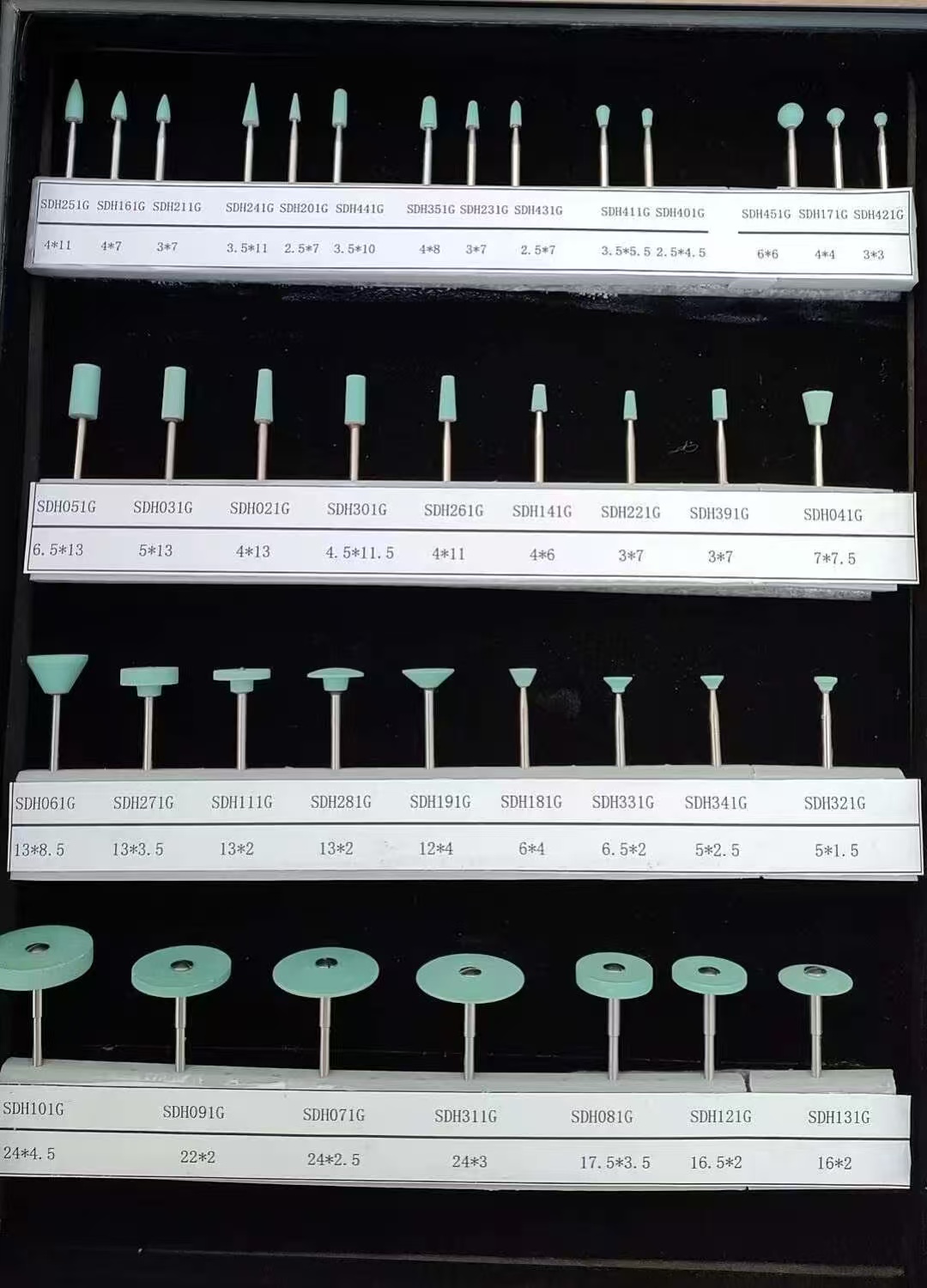

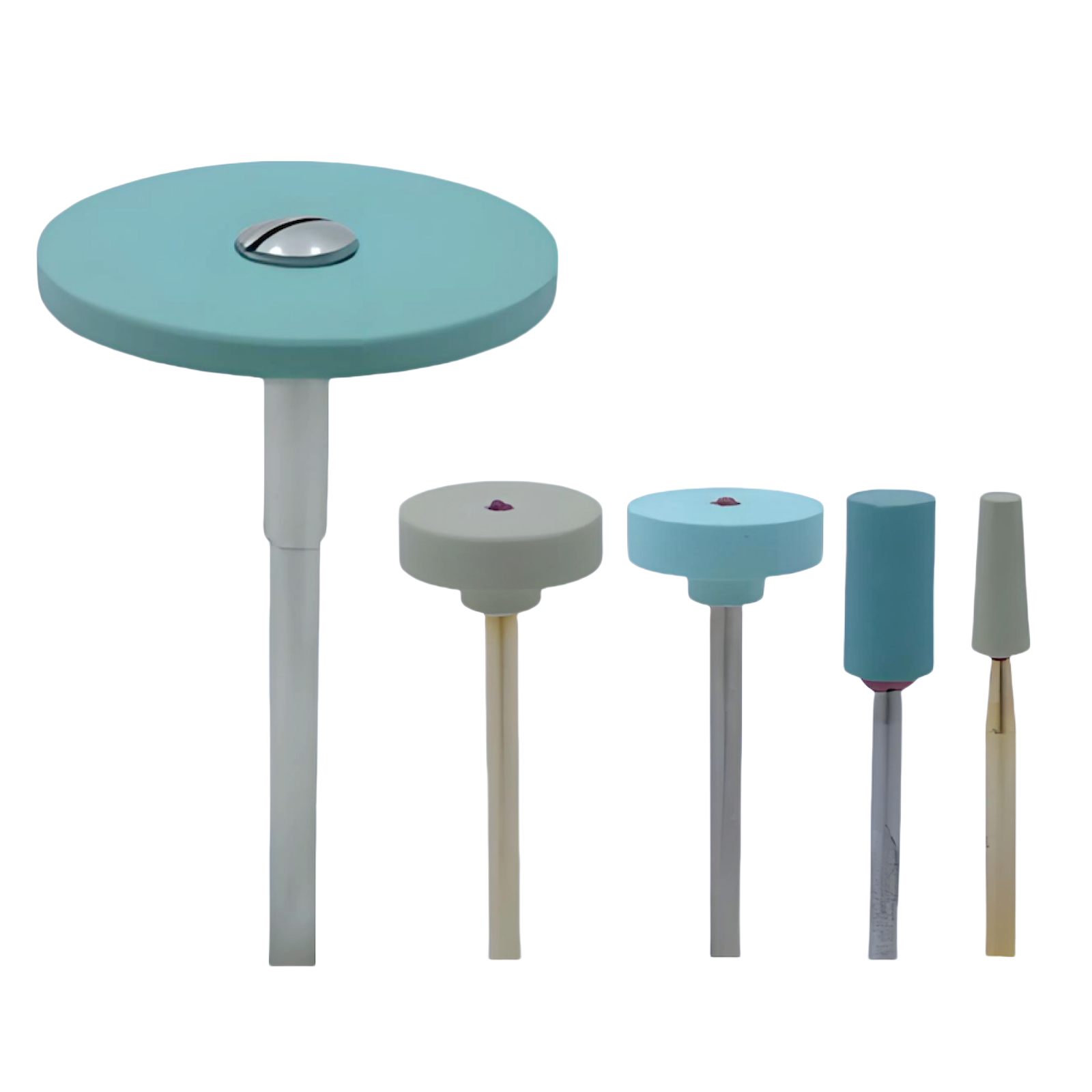

Product Diagram

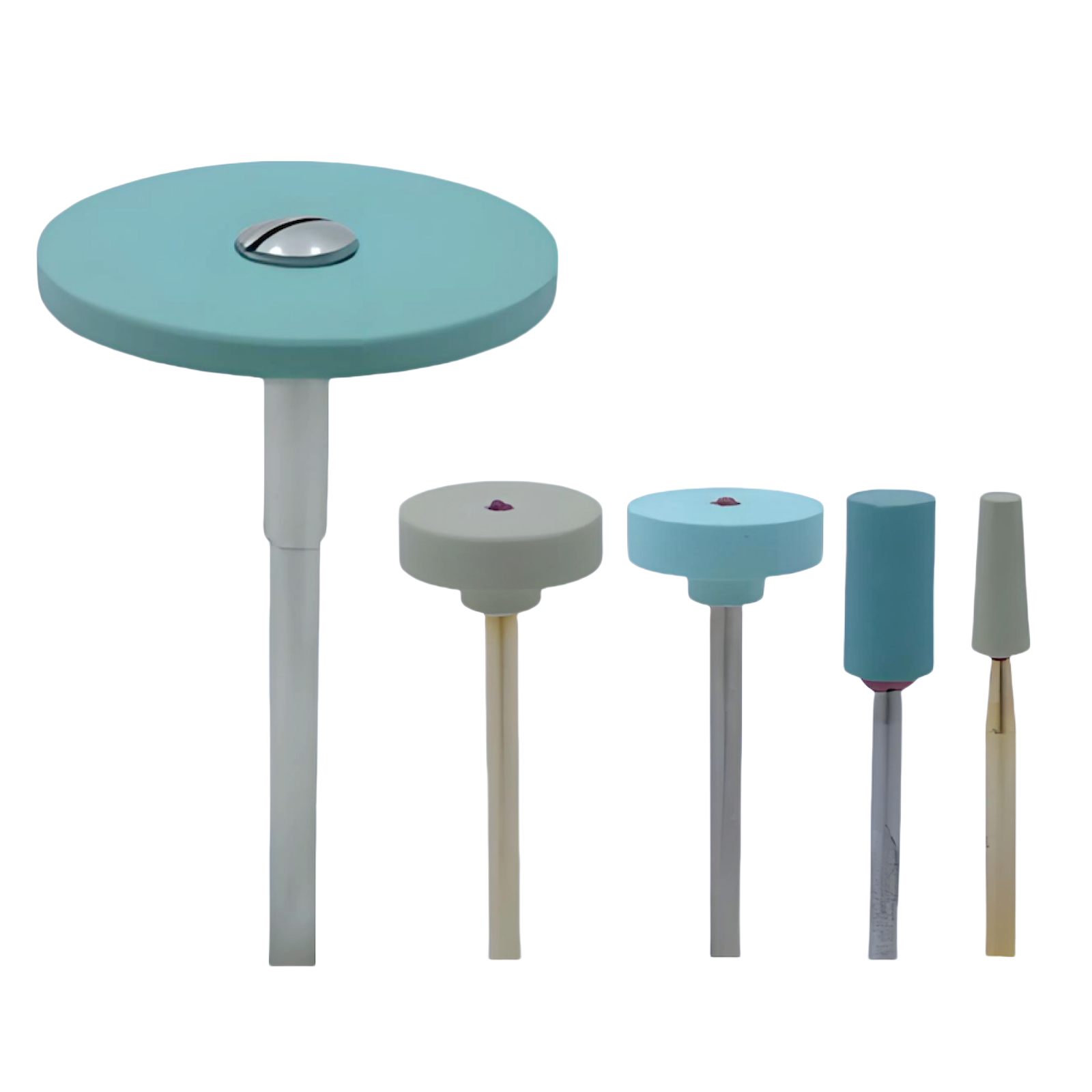

For fast finishing and removing zirconia workpiece, heatless, dry processing,smooth grinding,sharp and flexible, no cracking or damage.

Specification: includes item no., pack, grit, empf, max empf, size.

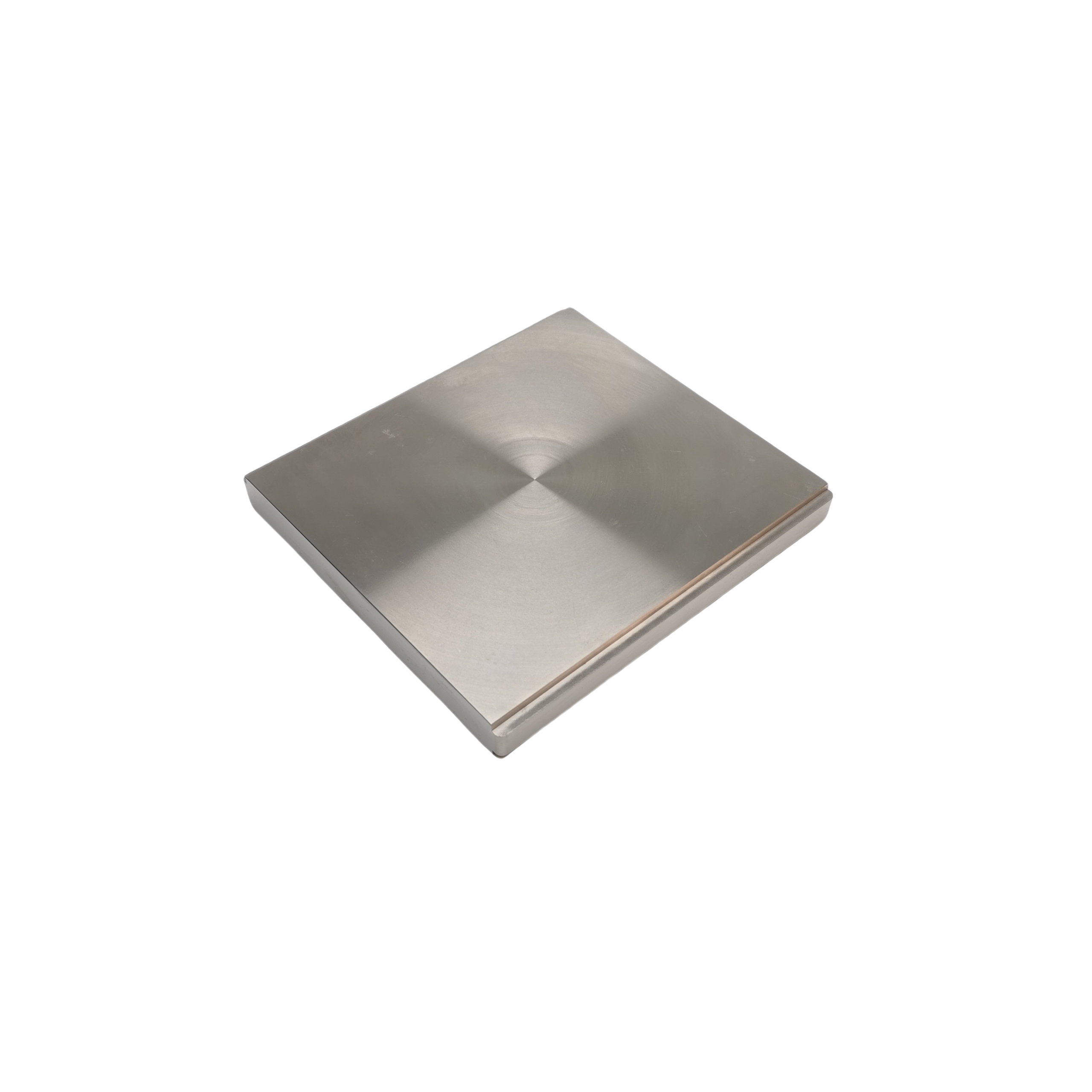

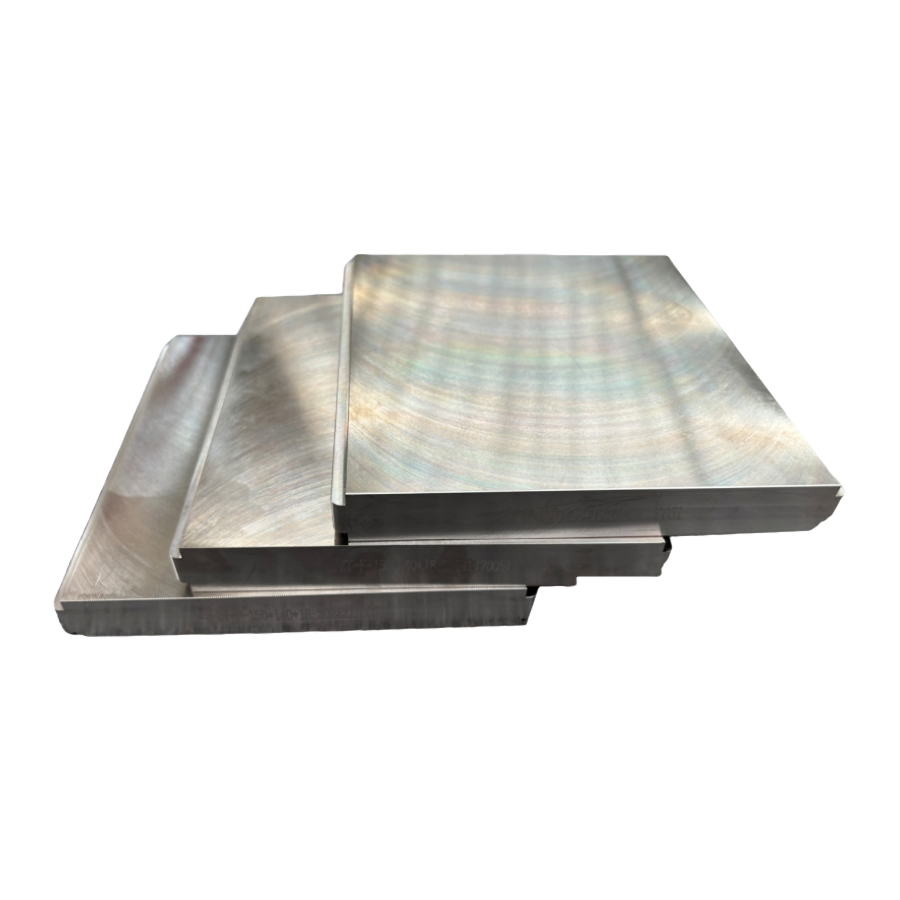

Gallery

Related News

The Ultimate Guide to Polishing Zirconia in 2025: A Complete Workflow from Pre-polishing to Mirror Finish In the modern dental […]