Stain Paste

Stain Paste Kit is a Simplified and Aesthetically Superior Solution for Zirconia Restorations. It’s a complete solution that includes a glaze, 3D natural shade, and essential liquids for dilution and refreshment, ensuring that every aspect of the staining process is covered.

Product advantage

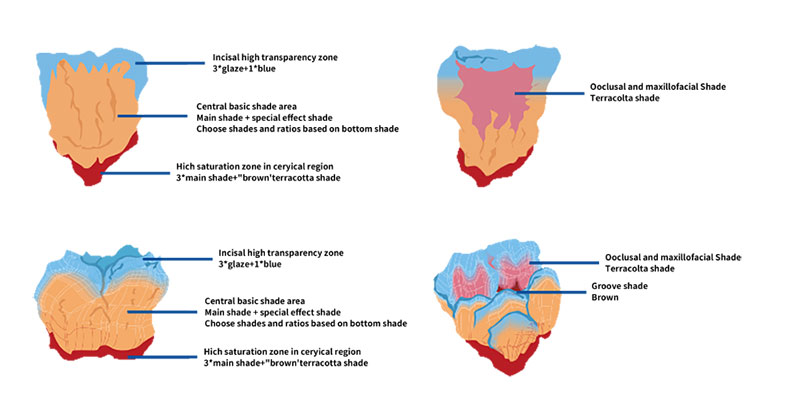

- Comprehensive Set: The set includes four main ABCD shades, 18 special effect colors, a glaze, a 3D natural shade, and both diluting and refreshing liquids.

- Ready-to-Use: The paste does not require the mixing of powder and liquid before use, which is convenient and time-saving.

- Integrated Glaze Ingredients: Each bottle of paste in the set contains ingredients for glaze, eliminating the need for a separate glazing application.

- Single Staining Process: The product aims to achieve the ideal effect through a single staining process.

- Customizable Shading: The shades from each paste can be freely matched to achieve a satisfactory effect on the crown’s shade and can be used directly after being mixed evenly.

Specification

Usage Method: as the figure shown

Storage Method: The product should be stored in dry conditions with an optimal temperature range of 12°C to 38°C. After use, the bottle cap should be tightly sealed, and the product should be kept in a hygienic environment.

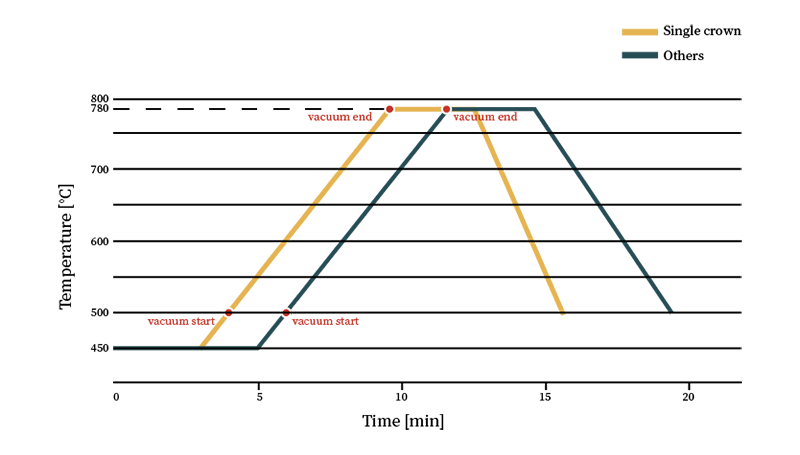

Standard Paste Sintering Curve

1. For glass ceramics

Firing temperature is between 740°C – 750°C, with full vacuum, 1min hold time.

2. For Full Zirconia

Firing temperature is between 900°C – 910°C.

3. For Porcelain Fused to Zirconia

Please follow manufacturers’ recommended glazing temperature. (For all PFZ, it is preferred to fire the staining and glazing separately).

4. For Porcelain Fused to Titanium

Firing temperature is between 900°C – 910°C.

5. For All high fusing PFM

Firing temperature will be 880°C, 30 second hold time.

| First sintering | Secondary sintering | Single crown laze sintering | Zirconia bridge intering(4-7 units) | Zirconia brdge sintering (8 units and above ) | |

| Hold time | 450 | 450 | 450 | 450 | 450 |

| rying time | 5 | 5 | 3 | 5 | 5 |

| Heating rate | 50 | 50 | 50 | 50 | 50 |

| Vacuum start temperature | 500 | 500 | 500 | 500 | 500 |

| vacuum end temperature | 780 | 780 | 780 | 780 | 780 |

| Sintering temperature | 780 | 780 | 780 | 780 | 780 |

| Hold time | 3 | 3 | 3 | 3 | 3 |

| low cooling | 5 | 5 | 5 | 5 | 5 |

| Take out temperature | 500 | 500 | 500 | 500 | 500 |